|

piektdiena, 13. februāris, 2026

|

|

|

|

Technical Partners International Inc. / TP Riga

Vienības gatve 109, Riga, LV-1058, Latvia  +371 29255223

,  SKYPE: ed.kalvins,  ed.kalvins@tpriga.lv ed.kalvins@tpriga.lv

|

|

|

|

Continuous Water Monitoring

Technical Partners is in the process of introducing a new water monitoring service to the Baltic region.

1 The SERVICE

Provide the services of a Mobile Lab

(ML) for monitoring pollution levels on a continuing basis in streams, rivers and lakes.

2 The TECHNOLOGY

The main analysers in the ML include

3 PARAMETERS MEASURED Technical Partners is in the process of introducing a new water monitoring service to the Baltic region.

1 The SERVICE

Provide the services of a Mobile Lab

(ML) for monitoring pollution levels on a continuing basis in streams, rivers and lakes.

2 The TECHNOLOGY

The main analysers in the ML include

3 PARAMETERS MEASURED

- Ultra HTO: TOC (total organic carbon), TC (total

carbon), TIC (total inorganic carbon), COD (chemical

oxygen demand) and TNb (total bound nitrogen)

- Nitrificant

Toximeter: Toxicity

- ISE + standard

addition: NH4,NO3,Na,K,Cd,Cl,F

- Photometer: SO4, PO4, NO2, NO3, TNb, TP, Fe,

Al

- Electrodes: pH,

conductivity, redox

- Weather station:

Temperature, wind, humidity, air pressure, rainfall

In total,

the mobile lab will be able to monitor more than 20 parameters automatically on

site.

=

4 How it WORKS

The ML is a trailer that is delivered to the water monitoring site. If electricity is available, it is connected to the trailer, if not the unit has its own power generator. Sampling devices are inserted into the water. The unit can be left unattended during the monitoring period. However, provisions must be made to ensure the systems security.

The ML is directly connected to the

Internet (via a separate secure server). The laboratory can be controlled and

monitored remotely. Data transfer takes place directly after the

measurements. The measurement results of all sensors, electrodes and

analyzers are immediately available to all project partners.

5 The BENEFITS

Regular sampling and laboratory analysis methods do not give an accurate picture of

peak pollution periods. The continuous sampling of the ML provides a more

accurate pollution profile during the monitoring period.

Monitoring results are objective and cannot be fabricated or altered.

Data is provided to a central computer and/or the clients computer on a

continuous basis.

Monitoring is easy for the company or organization wishing to conduct

water monitoring. There is no need to purchase equipment, maintain it or to

hire personnel who need to be trained to use the equipment. They just purchase

the service for the required period. There is no equipment or personnel idle

time, no vacations, no sick leave, etc. Usual rental periods are from 4 to 8

weeks.

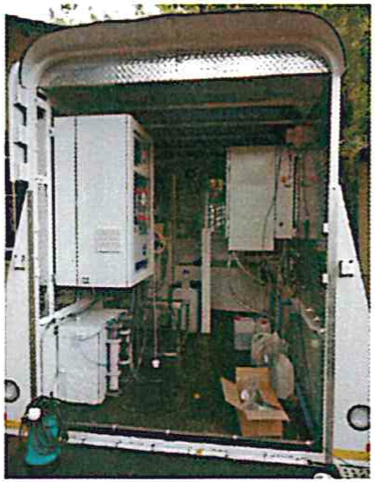

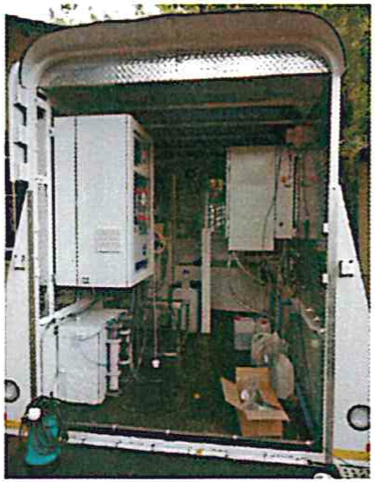

6 The MOBILE LAB

The aim of the mobile lab is to

support and improve current monitoring systems. It is a stand-alone solution

that applies the approach of innovative online analysis of water quality and

the fast and comprehensive data transfer to all partners and authorities

involved in the project in a practical manner. Using the ML for the monitoring

of diverse discharges from diffuse sources, from households, as well as industrial

pollution sources, it helps the Client prepare measures for water quality

improvement quickly with comprehensive and reliable information, enabling the

coordinated development and management of water, land and related resources. The ML is a trailer that is delivered to the water monitoring site. If electricity is available, it is connected to the trailer, if not the unit has its own power generator. Sampling devices are inserted into the water. The unit can be left unattended during the monitoring period. However, provisions must be made to ensure the systems security.

The ML is directly connected to the

Internet (via a separate secure server). The laboratory can be controlled and

monitored remotely. Data transfer takes place directly after the

measurements. The measurement results of all sensors, electrodes and

analyzers are immediately available to all project partners.

5 The BENEFITS

Regular sampling and laboratory analysis methods do not give an accurate picture of

peak pollution periods. The continuous sampling of the ML provides a more

accurate pollution profile during the monitoring period.

Monitoring results are objective and cannot be fabricated or altered.

Data is provided to a central computer and/or the clients computer on a

continuous basis.

Monitoring is easy for the company or organization wishing to conduct

water monitoring. There is no need to purchase equipment, maintain it or to

hire personnel who need to be trained to use the equipment. They just purchase

the service for the required period. There is no equipment or personnel idle

time, no vacations, no sick leave, etc. Usual rental periods are from 4 to 8

weeks.

6 The MOBILE LAB

The aim of the mobile lab is to

support and improve current monitoring systems. It is a stand-alone solution

that applies the approach of innovative online analysis of water quality and

the fast and comprehensive data transfer to all partners and authorities

involved in the project in a practical manner. Using the ML for the monitoring

of diverse discharges from diffuse sources, from households, as well as industrial

pollution sources, it helps the Client prepare measures for water quality

improvement quickly with comprehensive and reliable information, enabling the

coordinated development and management of water, land and related resources.

The ML is a trailer constructed and

equipped like a chemical laboratory. Protective measures are essential.

Additional equipment such as theft, burglary protection and safeguards for the

environment protection are indispensable and included.

The ML has an autonomous power supply

and is ready for operation quickly.

The ML is able to analyse the most important pollution sources directly on site either in online-mode or by single measurements and operates (24/7). Samples are also retained for further testing if required.

All analysers and sensors are part

of one water cycle to enable the relevant reference of each parameter and

measurement. The cycle starts with the sample being taken through a submersible

pump that is attached to a buoy. The submersible pump including the buoy is

directly connected to the ML.

In addition, the ML is equipped

with state-of-the-art analysers and

measurement methods in order to

receive accurate and reliable

monitoring data. The ultra high

temperature oxidation (HTO) at

1,200°C works without catalysts and determines the total

organic carbon (TOC) including

particles within a few minutes. Usually

catalysts wear out during operation

and may falsify results. Frequent

checks and calibrations are the

consequence resulting in additional

costs. Not using catalysts saves

on operating costs, eliminating the risk of inaccuracy and minimising maintenance efforts. Moreover, LAR's QuickTOC is even able to accurately analyse the most difficult samples containing high loads of particles without clogging or blockages. The special injection unit is specifically developed for such applications. This online analyser is additionally equipped with further detectors and determines the chemical oxygen demand (COD) and total bound nitrogen (TNb).

The online toximeter determines

toxic effects of pollutants on organisms using very sensitive bacteria that are

cultivated directly within the unit. The biomass is constantly

self-regenerating so that the analyser is ready to measure samples at any time.

For each measurement only a small amount of the test organisms are used. The

biomass culture within the fermenter is not contaminated. Since there is always

enough bacteria it is possible to operate this nitrificant toximeter either in

online mode as well as for the analysis of single samples. Usual toxicity tests

have a duration of some tens of minutes or even hours. This analyser's response

time is about 15 minutes.

Further methods and analysers allow

the determination of single pollutants such as ammonia, sodium, potassium, cadmium,

fluoride, chloride, nitrite, sulphate, and more. In addition to the water

parameters the lab records the most important parameters of the environmental

conditions including various weather parameters such as temperature, rainfall,

wind or humidity. Hence, the Client receives full information about the

meteorological conditions in addition to the water quality.

Depending on the samples`

composition and requirements, the following sample taking systems may be used:

The ML is a trailer constructed and

equipped like a chemical laboratory. Protective measures are essential.

Additional equipment such as theft, burglary protection and safeguards for the

environment protection are indispensable and included.

The ML has an autonomous power supply

and is ready for operation quickly.

The ML is able to analyse the most important pollution sources directly on site either in online-mode or by single measurements and operates (24/7). Samples are also retained for further testing if required.

All analysers and sensors are part

of one water cycle to enable the relevant reference of each parameter and

measurement. The cycle starts with the sample being taken through a submersible

pump that is attached to a buoy. The submersible pump including the buoy is

directly connected to the ML.

In addition, the ML is equipped

with state-of-the-art analysers and

measurement methods in order to

receive accurate and reliable

monitoring data. The ultra high

temperature oxidation (HTO) at

1,200°C works without catalysts and determines the total

organic carbon (TOC) including

particles within a few minutes. Usually

catalysts wear out during operation

and may falsify results. Frequent

checks and calibrations are the

consequence resulting in additional

costs. Not using catalysts saves

on operating costs, eliminating the risk of inaccuracy and minimising maintenance efforts. Moreover, LAR's QuickTOC is even able to accurately analyse the most difficult samples containing high loads of particles without clogging or blockages. The special injection unit is specifically developed for such applications. This online analyser is additionally equipped with further detectors and determines the chemical oxygen demand (COD) and total bound nitrogen (TNb).

The online toximeter determines

toxic effects of pollutants on organisms using very sensitive bacteria that are

cultivated directly within the unit. The biomass is constantly

self-regenerating so that the analyser is ready to measure samples at any time.

For each measurement only a small amount of the test organisms are used. The

biomass culture within the fermenter is not contaminated. Since there is always

enough bacteria it is possible to operate this nitrificant toximeter either in

online mode as well as for the analysis of single samples. Usual toxicity tests

have a duration of some tens of minutes or even hours. This analyser's response

time is about 15 minutes.

Further methods and analysers allow

the determination of single pollutants such as ammonia, sodium, potassium, cadmium,

fluoride, chloride, nitrite, sulphate, and more. In addition to the water

parameters the lab records the most important parameters of the environmental

conditions including various weather parameters such as temperature, rainfall,

wind or humidity. Hence, the Client receives full information about the

meteorological conditions in addition to the water quality.

Depending on the samples`

composition and requirements, the following sample taking systems may be used:

- The centrifugal separator (elimination of

coarse contamination),

- the relay-controlled sample taking system by

WaterSam (additional control samples or reserve samples), and

- the patented LAR Flow-Sampler (enables the

clogging-free sample taking).

The unique stand-alone character and

developed data transfer system of LAR, provides measurement results directly

via internet to the authorities and partners. Authorities and project partners

can use the results directly for further updates and evaluation.

The trailer has an approximate size

of 3 x 2 x 2 meters (length x width x height) and weighs less than 1 ton.

This ML needs a short set-up time to

be ready for operation on site.

Because of considerable differences

both of the water level and of the conditions of the riparian zones (interface

between land and a river or stream), sampling has to be carried out by a

special buoy which can be stored on the truck and easily positioned in the

river.

Being mobile, the laboratory is

applicable even to places that are difficult to access. Alongside rivers even

problematic measurement points can be reached.

The measurement period per location

is normally between 1 and 2 weeks.

There is

no longer a need to transport samples over long distances. The ML analyzes the major sources of pollution locally.

7 The TECHNOLOGY MANUFACTURER

LAR

Process Analysers AG of Berlin, Germany, developed into the leading supplier

of online analysers for the determination of sum parameters in water. See http://www.lar.com/. LAR has participated in a pilot project in South Africa by developing

and supplying a mobile laboratory (ML) for water monitoring.

See

http://www.lar.com/news-events/news-display/presse/zeige/Pressemeldung/iwrm-in-south-africa-lars-mobile-lab.html.

Technical Partners (TP Riga SIA / Technical Partners International Inc.) has represented LAR Process Analysers in the Baltic States since December, 2008. The TP Riga office is located in Riga at Vienības gatve 109.

Ed Kalvins BASc - Chemical Engineering (University of Toronto, Canada), Owner / Project Director. 40 years of Project Management, Manufacturing Management and Engineering Management experience in Canada and Latvia.

Alvis Līdums - BA Economics Manufacturing, BA Business Administration, MA Public Administration (University of Latvia). Project Manager. Industrial Engineering and Project Management experience. Technical specialist.

COMMERCIAL

ARRANGEMENTS

rental on a daily

basis at a rate determined by the requirements

Contact Information:

Ed Kalvins, +371

29 255 223 ed.kalvins@tpriga.lv SKYPE:

ed.kalvins

Alvis Līdums, +371

29 194 021 alvis.lidums@tpriga.lv SKYPE:

alvis.lidums1

back

back

|

| |

Technical Partners is in the process of introducing a new water monitoring service to the Baltic region.

Technical Partners is in the process of introducing a new water monitoring service to the Baltic region. The ML is a trailer that is delivered to the water monitoring site. If electricity is available, it is connected to the trailer, if not the unit has its own power generator. Sampling devices are inserted into the water. The unit can be left unattended during the monitoring period. However, provisions must be made to ensure the systems security.

The ML is a trailer that is delivered to the water monitoring site. If electricity is available, it is connected to the trailer, if not the unit has its own power generator. Sampling devices are inserted into the water. The unit can be left unattended during the monitoring period. However, provisions must be made to ensure the systems security.

+371 29255223

,

+371 29255223

,  SKYPE: ed.kalvins,

SKYPE: ed.kalvins,